MercoPress. South Atlantic News Agency

Falklands enters oil production stage: contract awarded for designing tension leg platform

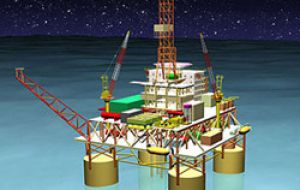

Prototype of TLP with over 30,000 tons of topsides for the 450-metres Sea Lion deep offshore location

Prototype of TLP with over 30,000 tons of topsides for the 450-metres Sea Lion deep offshore location International engineering and project management company, AMEC, will be the company responsible for designing Premier Oil’s tension leg platform (TLP) for the Sea Lion Development in the North Falklands Basin, 200 kilometers to the north of the Falkland Islands.

The company have been awarded a 12-month front end engineering design (FEED) contract.

The Sea Lion development includes plans for the TLP with over 30,000 tons of topsides for the 450-metres deep offshore location. The topside consists of a deck that houses the drilling and production equipment, as well as the power module and the living quarters.

AMEC’s scope of work includes engineering and procurement services for the TLP along with interface management and preparation of cost estimates and tender documents. AMEC will be responsible for the design of the TLP, with the potential to provide continued support to Premier through the detailed design and fabrication phases of the project.

“The FEED covers a fully integrated scope for the hull, production topsides and drilling facilities and will deliver a solution focused on constructability and operability,” stated a spokesperson for the company.

AMEC will carry out the project from its London design office, supported by subcontractors KCA Deutag in London and Houston Offshore Engineering in Houston.

“Large FEED contracts for oil and gas developments are a big part of AMEC’s green-field core business,” said Nick Shorten, Managing Director of AMEC’s Greenfield business.

“We are delighted to have the opportunity to work with Premier for the first time.”

Some of AMEC’s other customers include BP, Shell, and the US Navy.

The Sea Lion field is located approximately 200 kilometers north of the Falkland Islands.

Phased production is planned from a central TLP, with future subsea tiebacks. The TLP will contain drilling, topsides well processing facilities and utilities with oil export being undertaken via a separate Floating Storage and Offloading unit.

Chief Executive Officer of Rockhopper, which has 40% interest in Sea Lion, Sam Moody, commented: “We are delighted that the FEED contract for the Sea Lion field has been formally awarded to a world class engineering firm such as AMEC.

“This is a highly significant milestone in our plans to develop the discovery and comes on the back of our recent announcement that a rig has been signed to undertake a new exploration drilling campaign in the North Falkland Basin early next year.

“We look forward to continuing to work closely with Premier as we move the Sea Lion project towards Final Investment Decision.”

TLP facts

*A TLP is a buoyant production facility (pictured) vertically moored to the seafloor

by tendons.

*The buoyant hull supports the platform’s topsides, an intricate mooring system keeps the TLP in place.

*The buoyancy of the facility’s hull offsets the weight of the platform, requiring clusters of tight tendons, or tension legs, to secure the structure to the foundation on the seabed.

The foundation is then kept stationary by piles driven into the seabed.

*The basic design of a TLP includes four air-filled columns forming a square. These columns are supported and connected by pontoons, similar to the design of a semisubmersible production platform.

*A TLP allows for horizontal movement with wave disturbances, but does not permit vertical, or bobbing movement. (PN)

Top Comments

Disclaimer & comment rules-

-

-

Read all commentsWill they be harrassed by the Argentine navy while they carry out their business? They need to keep an eye out for rowing boats.

Jul 18th, 2014 - 09:18 am 0@1... and the elite “Dora the Explorer” class dinghies.

Jul 18th, 2014 - 09:36 am 0Oh how I wish the argies were stupid enough to try interfering with the construction / location of the platform.

Jul 18th, 2014 - 11:13 am 0But even TMBOA is not that stupid but in any event she will be long gone before construction on the sea bed commences.

Commenting for this story is now closed.

If you have a Facebook account, become a fan and comment on our Facebook Page!